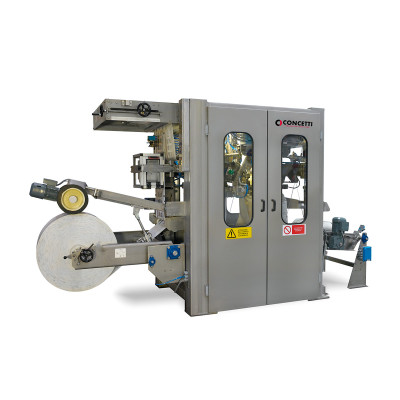

FFS-E

FFS-E

The FFS-E (Form - Fill - Seal) machine is designed to reach very high capacity outputs, over 2000 bags/hour, according to the product characteristics. The FFS-E is suitable for packing free flowing products.

It is equipped with three operating stations: one for the bag bottom formation and the film cut based on the desired length, the second for the filling and the third for the bag top sealing.

Specifically designed Concetti technical solutions, both on the mechanical and the electronic level, allow the machine to reach the requested very high capacities.

The operation phases and the change of the functional parameters are PLC-managed; the product or format change occurs in very short time and without any intervention by the operator thanks to the actuators installed.

Thanks to its limited size, FFS-E is fit to be installed in any production site; its monobloc structure is open on the bottom, making the cleaning and inspection operations extremely comfortable, and its inspection doors ensure a maximum safety for the operators.

Technical Data

| Max. productions | 2000 b/h |

| Reel Ø max | 1500 mm |

| Bag weight | From 10 to 40 kg |

| Bag length | min 550 max 1000 mm |

| Bag width | min 320 max 420 mm min 280 con with a special bag-holder |

| Gusset depth | min 40 max 90 mm |

| Film thickness | 80-250 µm |

| Power supply | 380 V- 50 Hz |

| Installed power | 18 kW |

| Compressed-air consumption | 110 Nl/cycle |

| Standard degree of protection | IP 55 |

| Self-diagnostic system | |

| Soundproofing | |

| Contact parts in stainless steel |

- Servo-assisted system for the tubular reel change

- Micro-perforation of the reel to evacuate the air inside the bag

- Probe to evacuate the air from the filled bag

- 45°-sealing for the bottom and top corners of the gusseted bags

- Device to translate the machine under multiple feeding points (silos) and work different types of products

- Protection rate IP 65

- Alphanumeric print on one or two sides of the tubular reel

- Punch device to create handles during the bag-formation stage

- Device to create gussets from a flat tubular reel

- Product deareation system by means of probes

- Possibility to produce the whole machine in stainless steel

- Structure painting with epoxy cycle

NOTE: The information listed in the chart is strictly indicative and will depend on the specific features of each machine.

.jpg)

.jpg)