Low Density Powders | Weighing | Bagging | Palletising

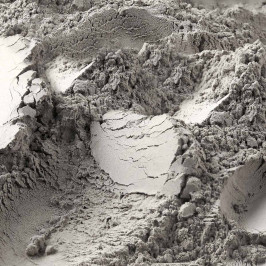

Low Density Powders

IMPROVING LOGISTICS WITH CONCETTI FFS SYSTEM FOR LIGHT BULK DENSITY POWDERS

Recently Concetti have scored successes with their new fully automated FFS bag filling lines for light bulk density powders. Upgrading an old-style valve bagger to the FFS technology allows the bag shape and dimension to be optimised, thus producing drastic improvements in the whole logistic chain, and appealing cost saving.

Previously, these powders were packed into paper valve bags but after preliminary tests, Concetti proposed a “Continua 600” Tubular Form, Fill, Seal machine with screw fed gross weigher for 10 to 15Kg bags. Concetti has now implemented the use of special dosing augers to increase the product density, increase performance and optimise the bag dimensions.

With de-aeration lances to remove air from the product during and after filling, the “Continua” produces a more compact bag. Sack mouth cleaning ensures a perfect seal every time and corner sealing can be added to further improve the finished bag shape. The unit is fitted with stainless steel material contact parts throughout.

Filled and sealed bags pass through a flattening device and are then palletised by either the Concetti “PS-4A/3S-C” single column robot palletiser or other model of palletising robots.

All the Concetti lines feature easy to use touch screen operator interface and are fitted with a remote teleservice facility in addition to Concetti’s normal Hot-Line telephone support.

This all demonstrates how Concetti apply FFS technology to reduce costs while providing a more secure pack.