Powder Bagging Machine

Powder Bagging Machine

-

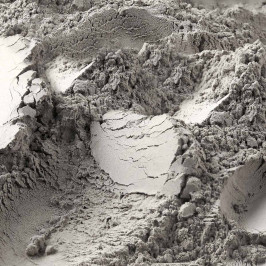

Improving your logistics with Concetti FFS Powder Bagging machine for light bulk density powders, that allows the bag shape and dimension to be optimized.

Recently, Concetti have scored successes with their new fully automated FFS powder bagging machines for light bulk density powders. Upgrading an old-style valve bagger to the FFS technology allows the bag shape and dimension to be optimized, thus producing drastic improvements in the whole logistic chain, and appealing cost saving.

How the Concetti powder bagging machine came about

Previously, these powders were packed into paper valve bags but after preliminary tests, Concetti proposed a Continua Tubular Form, Fill, Seal Powder Bagging Machine. The improved bags offer higher tensile strength, minimization of nuisance dust and greater control of moisture to maintain the integrity of the material inside.

The Huber installation consists of two complete Form Fill Seal powder bagging machines each with a gross weigher and a complex densification screw feeders, including a double air evacuation process. Both powder bagging machines are delivering filled bags to a 4 column robot palletizing machine. Output is 150 bags/hr with 10 kg bags = 1500 kg/h (3306 lbs/h).

The advantages of the powder bagging machine by Concetti

With deaeration lances to remove air from the product during and after filling, the FFS Powder Bagging Machine Continua produces a more compact bag. Sack mouth cleaning ensures a perfect seal every time and corner sealing can be added to further improve the finished bag shape. The unit is fitted with stainless steel material contact parts throughout. The new packaging is also easily recyclable.

Filled and sealed bags pass through a flattening device and are then palletized by either the Concetti PS-4A/3S-C single column robot palletizer or other model of palletizing robots.

Concetti Customer Service for FFS powder bagging machine

Concetti remains at its customers' side throughout the powder bagging machine lifecycle, thanks to the new Check services, Customer Help Care Kit for field and remote assistance. Alongside a range of digital services (customer portal, Check app, smart glass assistance, etc.), our customers can rely on direct support from local service centers (Campinas, SP, Brazil and Braselton, GA - US) with teams of experienced technicians who can travel directly to the site upon request. In addition, there is an appreciated training service for customer personnel in the proper use of the machines.

All the Concetti lines feature easy to use touch screen operator interface and are fitted with a remote teleservice facility in addition to Concetti’s support. This all demonstrates how Concetti applies FFS technology to reduce costs while providing a more secure pack.

CASE STUDY from Powder & Bulk Solids: Fine Powder Bagging and Palletizing

Are you willing to have more information about our powder bagging machines? Request an offer!