Concetti has recently supplied a producer of high quality fishmeal with a fully automatic weighing and bagging system with a production capacity of 1200 bags / hour (25 kg bags).

The customer's objective was to automate and increase the packaging output, strongly influenced by the characteristics of the product – a semi free flowing mixture of coarse and fine powders. The behaviour of the product changes during the process, the most challenging being the tendency to clump.

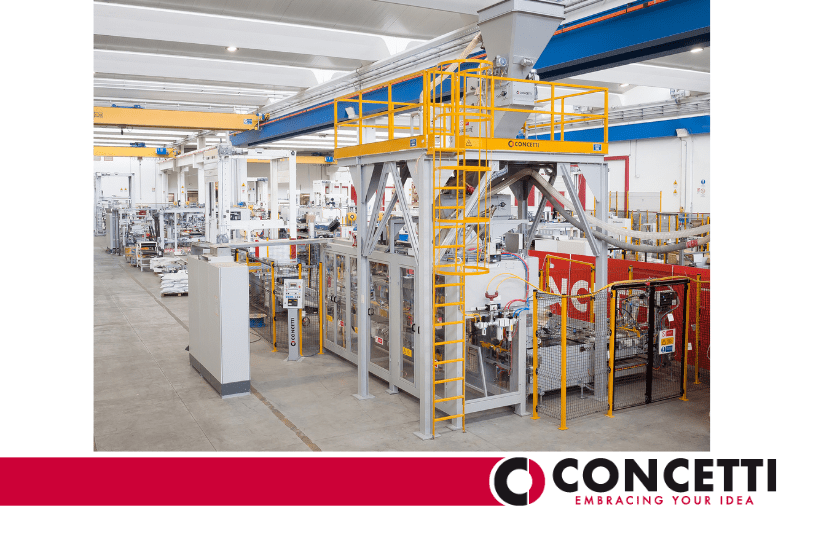

Concetti – an Italian manufacturer of weighing, bagging and palletising systems, with experience in the handling of special and variable-density products – selected the proven belt fed NET/N weighing scale combined with an intermediate discharge belt that accurately regulates the flow of product to the bag holder, designed for rapid bag filling. In addition, the reduction of air contained in the bag ensures a long-lasting attractive pack and great pallet stacking qualities.

The IGF 1200 bagging machine stands out for its great versatility. The self-adjusting features of the various components of the system enables one machine to fill and perfectly close pillow or gusseted bags in the range of 10-50 kg, for Paper, PE or WPP. The bag closing system is either by stitch or heatseal. To minimize setup times, the PLC-assisted format change is fully automatic - in just 60 seconds - without any operator intervention whatsoever. A powerful versatility that can be also be found in the integration of ultra-modern labelling, coding and bag printing systems that transforms packaging by communication.

The packaging project was carried out in close collaboration with Boga Tecnica, sales partner of Concetti in Spain, Portugal and Chile.