Fertilizer bagging machine | Granular and powdered

Fertilizer bagging machine

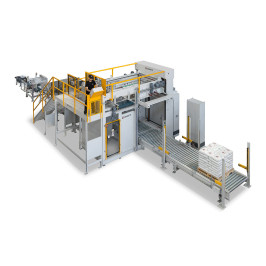

High speed fertilizer bagging and palletizing machine

Concetti have now enhanced their product range for the fertilizer industry with a new high speed bagging machine and robot palletizer featuring a full stainless steel gripper that picks up two bags at a time from the service roller conveyor and places them at a point assigned by the program on the pallet, reaching a production output of up to 1.600 bags/h.

The Concetti have a long reference list of successful fertilizer packaging machines for chemical and organic products, ranging from free flowing granules - e.g. NPK, urea, phosphates, ammonium sulfate etc. - to powdery fertilizers with particular size ranging from a few dozens microns to some tenths of centimeter.

Concetti proposes turn-key fertilizer bagging equipment based on either FFS or open-mouth bag technology.

Searching for reliable bagging or palletizing equipment for fertilizers?

FFS-E - Fertilizer bagging machine

Fed by one gravity net weigher, the Concetti FFS-E class of Form Fill Seal machines is particularly suited for bagging fertilizers in pack sizes ranging from 10 to 50 kg, made from a PE tubular reel, with a maximum capacity of 2,000 bags/hour.

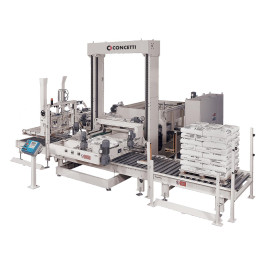

Starpack® packaging system for fertilizer industry

For the clients who prefer to use pre-made open mouth bags made from paper, PE or woven polypropylene, the answer is the Starpack® fertilizer bagging machines reaching up to 1,600 bags/hour.

Bulk bag fertilizer machine

Particularly effective for fertilizers are the Concetti bulk bag installations.

This type of machine is used to bag fertilizers in big bags ranging from 400 to 1200 kg, made of woven polypropylene with internal liner (single loop or four loops) and can guarantee capacities up to 100 bags/hour.

Due to the particularly aggressive nature of chemical fertilizers, the materials employed for the manufacture of these installations are of extra high quality, with a wide use of stainless INOX AISI 304 or 316L steel for all parts in contact with the product. These may be subjected to additional treatments to reduce even further the possibility of corrosion.

Choosing a bagging line by Concetti is a guarantee of packing fertilizers with high speed, absolute weighing accuracy and long-lasting reliability.

Are you looking for bagging or palletizing equipment for fertilizers?