High-level

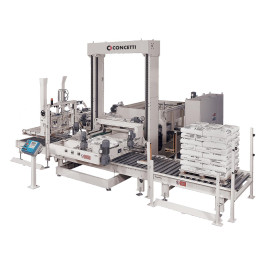

High-level palletizer

The high-level push-type palletizer is particularly suited for achieving high speeds with stable bags that have a well-defined shape. It is made of a high-level rigid case palletizer with a vertical frame: we will explain it in the paragraph below its function.

The fact that different operations are performed simultaneously means the machine can reach high production capacities that otherwise would be impossible to achieve.

How a high-level palletizer is made and how it works

The machine is composed of a rigid high-level case palletizerwith a vertical frame sliding on it and this holds the pallet being formed. The full bags coming from the filling line are raised to an orienting device.

Following the programmed palletizing pattern, the bags are initially arranged on the row-formation roller conveyor and then when a row is composed, it is shifted to a temporary parking area. When the last row completes the layer, a pusher shifts the entire layer over two sliding trapdoors that centrally unload the layer, which is then compacted on all four sides.

At this point, the doors open and unload the just-formed layer onto the pallet being made, and the frame that holds it is lowered by the thickness of one layer. The cycle begins again until the pallet has been completed, at which point the frame descends to the level of the evacuation roller conveyor.

Through this roller conveyor, the pallet is ejected and is sent to the parking roller conveyor. At the same time, a new empty pallet will have reached the mobile frame, which is raised to the height of the trapdoors to receive the first layer that has been prepared and start the new cycle.

Concetti high-level palletizer: easy to perform

The use of a PLC operating system and the presence of special actuators makes the procedures to change the format or program extremely fast and easy to perform. Different palletizing patterns can be memorized in the PLC for easy execution.

The high-level palletizer comes complete with a treading platform to access the elevated parts of the machine, an empty-pallet magazine, an evacuation roller conveyor and a full-pallet parking roller conveyor.

The push-type palletizer comes complete with safety devices compliant with current international standards.

How high-speed bag palletizer can improve your performance

Concetti's mechatronic innovation has been taken to new heights of precision. Our high-speed bag palletizers have been designed to enhance the quality of your products without compromising the smoothness of industrial palletizing operations.

If you are looking for an efficient machine capable of managing the most diverse bag formats and that can be integrated into an existing packaging line, then Concetti has the right solution for your activity.

Our high-speed palletizers:

- feature high-grade and hygienic materials

- display a PLC operating system

- reach a speed rate up to 2,700 bags per hou

- their maximum palletizing load height is of 2,000 mm, including pallet height.

About Concetti’s assistance

Digital Help Care

Il nuovo supporto multicanale Check consente la risoluzione rapida di tutte le problematiche dei clienti, attraverso un portale web, ticket assistenza personalizzati, FAQ, e assistenza in mobilità attraverso la app per smartphone “Concetti Check”. La app consente di sfruttare video, chat, sms per scambiare informazioni e ricevere assistenza immediata.

Hotline

Concetti offers specialized support from a team of technicians for high-level palletizers remote assistance. 84 % of issues are solved remotely or through the teleservice connection with the plant.

On-site

If necessary, Concetti will send its technicians directly on-site for a rapid resolution of problems that cannot be solved remotely. Plus, we have a team for technical maintenance of your palletizing equipment.

Training

After installation on site, we provide your team with all the necessary training to solve any issues related to the high-level palletizer.

TECHNICAL DATA

| Maximum speed | up to 2,700 b/h, depending on the number of bags per layer |

| Workable bag weights | up to 50 kg |

| Minimum pallet dimensions | 800 x 1200 mm |

| Maximum pallet dimensions | 1100 x 1300 mm |

| Maximum palletized load height | 2000 mm, including pallet height |

| Maximum full pallet weight | 2000 kg |

| Operating system | PLC |

| Power supply | 380 V- 50 Hz |

Otions for Concetti high-level palletizers

- Teflon finish of the trapdoors for working with plastic bags.

- Parts in contact with the bag (rollers, plates, etc.) in stainless steel.

- Dispenser for placing cardboard or Moplefan sheets on the pallets.

- Dispenser for placing a plastic mesh sheet between the different layers.

- Possibility of working with pallets higher than 2,000 mm.

For non-standard pallet dimensions, the technical feasibility of the plant must be confirmed.

NOTE: The information listed in the chart is strictly indicative and will depend on the specific features of each machine.