Palletizing technology has changed over the last few decades. Conventional palletizers are valuable solutions, but they risk of being replaced by robotic palletizers that promise to be more performing (and economic), with a swift in daily industrial operations.

On this page, we will focus on the main features and advantages of these two systems, emphasizing the differences between a conventional palletizer and its robotic counterpart, as well as diving into their multiple applications.

The Main Advantages and Differences of Both Conventional Palletizers and Robotic Palletizers

Optimizing packaging operations has become instrumental in a world where performance go hand in hand with speed. Here, you can find a comprehensive overview of the main advantages of both conventional and robotic palletizing systems.

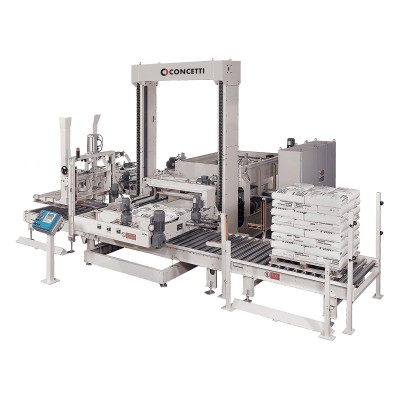

Conventional Palletizer

This model offer several benefits for businesses, as it has been designed to handle operations quickly and securely.

One of the main aspects of this palletizing solution is that it can deal with high-production demands. In fact, during processing, they usually form and compact layers on four sides, creating stable pallets that can withstand the challenges of transportation without incurring in damages.

Conventional palletizers are ideal if you are looking for a system that can manage a broad range of products, - from building materials to chemicals - integrating seamlessly even in existing productive plants.

A cost-saving feature that characterizes these traditional models is that they require minimal maintenance, reducing technical downtime for high efficiency.

Discover our conventional palletizers

Robotic Palletizers

On the other hand, robotic palletizers bring a new level of adaptability and accuracy to palletizing procedures. They are the perfect combination of engineering and the most advanced technology, two pillars of the modern industry.

No matter what size, shape or texture, robotic models are more flexible than conventional palletizers. They are suitable for industries with varied packaging requirements, as they are PLC-controlled. Consequently, the operators can select the parameters based on the type of operation they need to process, guaranteeing an optimal use of space and improved load stability. Usually, robotic palletizers are preferred by companies with limited production space, because they are more compact and space efficient.

While conventional palletizers are high-speed models, robotic systems can achieve a superior level of precision, delivering consistent, well-form pallets, even in case of delicate or irregularly shaped items.

Another feature is the modular design of robotic palletizers, which can integrate in any existing line thanks to their scalable nature. They respond to the increasing production demands of the market, enhancing the overall efficiency of the plant.

The automation behind this type of palletizer allows reducing manual labor, with minimal operational costs. Ultimately, this is a safer solution as it prevents the risk of workplace accidents.

Know more about Concetti robotic palletizers

The Applications of Conventional and Robotic Palletizers

Over the years, Concetti has improved its palletizing technologies to adapt to the new requirements of a vast array of industries. For this reason, we have decided to differentiate our offer with two lines - one of conventional palletizers, with a focus on high-speed production; and the other that aims at delivering superior efficiency and precise pallets.

Here you can find a list of the most common applications for both models.

- Cereals and powdery products require swift processing, therefore conventional palletizers are the best solution for bulk materials.

- Even when it comes to seasonal agricultural cycles, traditional models are more efficient, as they can handle large quantities of fertilizers in a short period of time.

- Another application conventional palletizers excel in is the management of heavy building materials, such as cement, that can be difficult to safely stack for transportation.

- When it comes to frits or dyes for ceramics, the best palletizing solution consists of choosing a robotic model, which can effectively prevent contamination during pallet formation.

- Plastic granules' spillage is a problem that can be solved thanks to a robotic palletizing system that preserves the product integrity during transportation.

- Another application is related to pet food and animal feed. Due to the fact that robotic palletizers, including combined palletizers (LAMPO) known for their high-speed capabilities, can deal with irregular shapes and sizes, this aspect secures packaging while maintaining product quality.

Are you interested in our conventional and robotic palletizers?