Discover all you need to know about the FFS-E salt bagging machine by Concetti - designed to be compact, and resistant at all times. Concetti produces a bagging machine specifically designed for granular, free flowing and non-dusty products, like sea salt and rock salt.

On this page, we will dive into:

- Salt bagging equipment: machines and palletizers

- FFS-E salt bagging machine characteristics

- Push-type high-level palletizer is the best solution for salt bags

- How salt bagging equipment works

- Maintenance and repair

- Why choose Concetti North America

Salt bagging equipment: machines and palletizers

Concetti offers a full range of bagging machines and palletizers specifically designed for salt bagging.

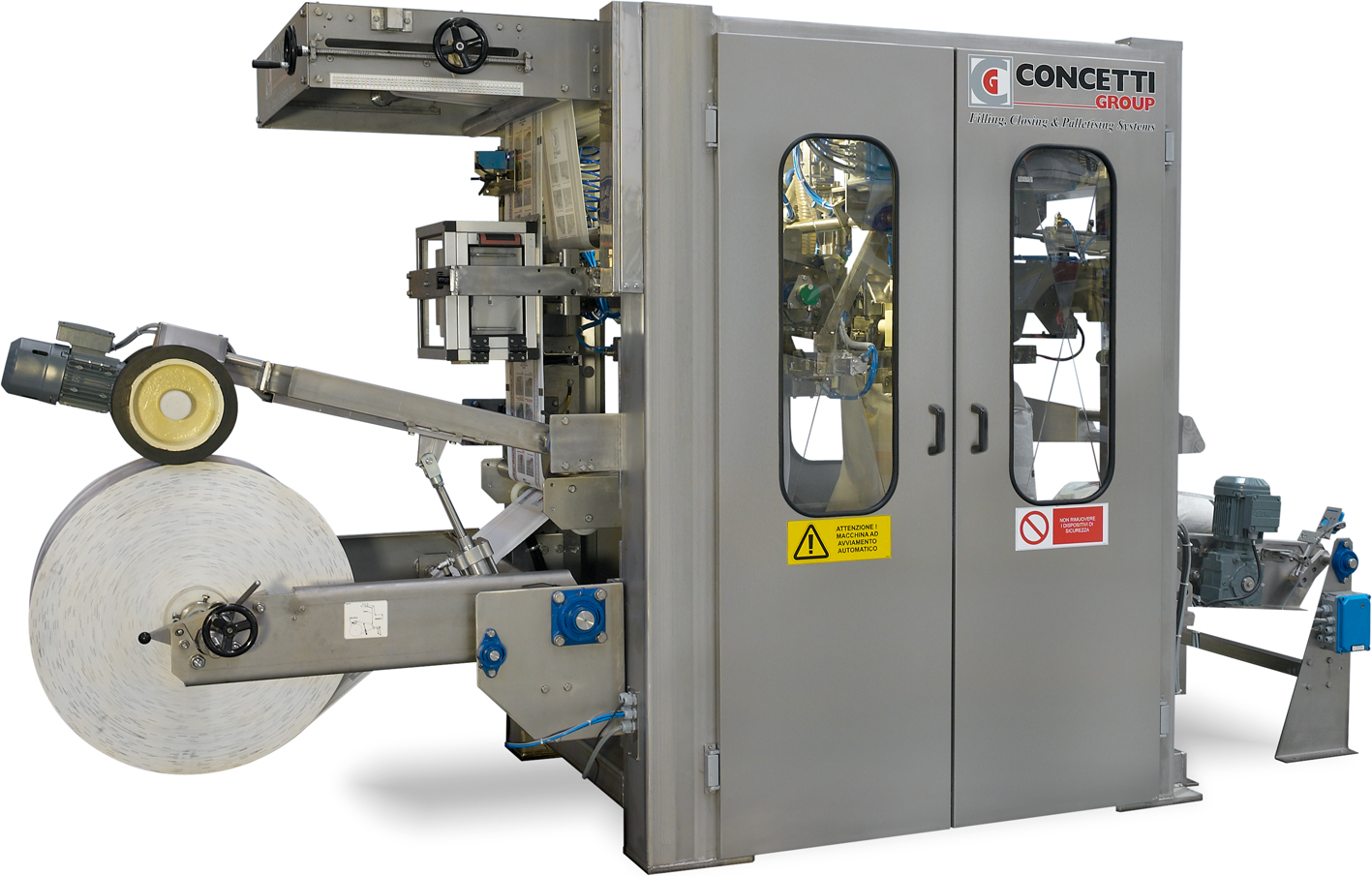

FFS-E salt bagging machine characteristics

The FFS-E salt bagging machine by Concetti is the epitome of compactness, precision, and efficiency. It has been designed to reach very high capacity outputs, with over 2000 bags/hour. Equipped with three operating stations, this machine has unique electronic and mechanical performances, which pinpoints once more the reliability and consistency of Concetti’s machinery.

FFS-E is not only a salt bagging machine, but it is a versatile solution that can deal with many materials in a unique way. Thanks to a close collaboration between our experts and the customers, this equipment can be customized.

Concetti has the aim to meet your expectations and go past them, delivering excellent machinery that can deliver what you require seamlessly without compromising on quality and the operators’ safety.

Technical Data

| Max. productions | 2000 b/h |

| Reel Ø max | 1500 mm |

| Bag weight | From 10 to 40 kg (20-94 lb.) |

| Bag length | min 550 max 1000 mm |

| Bag width | min 320 max 420 mm min 280 con with a special bag-holder |

| Gusset depth | min 40 max 90 mm |

| Film thickness | 80-250 µm |

| Power supply | 380 V- 50 Hz |

| Installed power | 18 kW |

| Compressed-air consumption | 110 Nl/cycle |

| Standard degree of protection | IP 55 |

| Self-diagnostic system | |

| Soundproofing | |

| Contact parts in stainless steel |

Optional features for FFS-E packing machine

The FFS packing machine can be equipped with the following optional features:

- Servo-assisted system for the tubular reel change

- Micro-perforation of the reel to evacuate the air inside the bag

- Probe to evacuate the air from the filled bag

- 45°-sealing for the bottom and top corners of the gusseted bags

- Device to translate the machine under multiple feeding points (silos) and work different types of products

- Protection rate IP 65

- Alphanumeric print on one or two sides of the tubular reel

- Punch device to create handles during the bag-formation stage

- Device to create gussets from a flat tubular reel

- Product deareation system by means of probes

- Possibility to produce the whole machine in stainless steel

- Structure painting with epoxy cycle

NOTE: The information listed in the chart is strictly indicative and will depend on the specific features of each machine.

Are you looking for a perfect salt bagging machine?

Our FFS salt packing machine compactness

One of the most relevant characteristics of the FFS-E salt bagging machine by Concetti is its compact size.

Being thoughtfully engineered to be placed even in the most narrow places, this machine can be located in any production site.

Moreover, it displays a monobloc structure, which is particularly user-friendly design-wise. Maintenance operations and cleaning are much easier thanks to an opening at the bottom which enables the operator to reach every corner of the machine.

Safety is another priority for Concetti. This is why FFS-E has inspection doors which allow the machine to be more productive but also to ensure the maximum level of security to the operators.

This salt bagging machine is synonymous with efficiency, simplicity, and most importantly, puts the safety of the operators first.

The process of salt bagging through FFS-E

Diving into the mechanics of the FFS-E equipment, we can definitely perceive that this is not just a functional and solid machine. In fact, it is extremely fast in delivering the bags requested as well as being astonishingly accurate in order to lower product waste.

Another feature which needs to be emphasized is that the whole structure of this machine is built using top-quality, corrosion-resistant and durable materials such as stainless steel. This is an important characteristic in machinery that needs to be easily cleaned internally because of the corrosive action of salt products. Furthermore, Concetti has automated the entire packaging process. Now, the operators only need to set the parameters correctly and wait for the PLC-managed machinery to deliver the exact amount of bags required.

Push-type high-level palletizer is the best solution for salt bags

Salt packaging is much more complicated than it appears on the outside. For this reason, it is instrumental to reach optimal storage and transport conditions in order to preserve the intrinsic qualities of this product.

It is not a mere coincidence that the push-type high-level palletizer, when combined with an efficient salt bagging machine, can help you achieve perfect packaging results.

It is essential to keep in mind that salt is inherently dense and it can be well distributed in bags. This palletizer model has been conceived to manufacture stable and cubic pallets.

In this way, space is optimized and salt can be safely stacked. The future of storage lies in the synergistic work of the FFS-E salt bagging machine with this push-type high-level palletizer.

TECHNICAL DATA

| Maximum speed | up to 2,700 b/h, depending on the number of bags per layer |

| Workable bag weights | up to 50 kg |

| Minimum pallet dimensions | 800 x 1200 mm |

| Maximum pallet dimensions | 1100 x 1300 mm |

| Maximum palletized load height | 2000 mm, including pallet height |

| Maximum full pallet weight | 2000 kg |

| Operating system | PLC |

| Power supply | 380 V- 50 Hz |

Otions for Concetti high-level palletizers

- Teflon finish of the trapdoors for working with plastic bags.

- Parts in contact with the bag (rollers, plates, etc.) in stainless steel.

- Dispenser for placing cardboard or Moplefan sheets on the pallets.

- Dispenser for placing a plastic mesh sheet between the different layers.

- Possibility of working with pallets higher than 2,000 mm.

For non-standard pallet dimensions, the technical feasibility of the plant must be confirmed.

NOTE: The information listed in the chart is strictly indicative and will depend on the specific features of each machine.

Discover more about our push-type high-level palletizer

How salt bagging equipment works

How does the salt bagging process work through the FFS-E system?

- Firstly, the machine shapes bags starting from a pre-made PE tubular film. Length can vary due to the parameters set for that butch.

- Then, bags are filled with salt. Thanks to an automated weighing system, FFS-E knows exactly when to stop in order to provide just the right amount of product.

- Once the filling step is over, the machine proceeds with sealing, a very delicate phase that can affect the purity and freshness of salt.

- Lastly, bags are palletized so that they can be easily transported.

FFS-E optimizes the manufacturing process ensuring that not a single grain of salt is wasted. But this is not it.

Concetti cares about the environment and, for this reason, FFS-E can work successfully with different types of packaging, even recycled ones, in order to be greener in an industry which deeply values sustainability.

Last, but not least, this machine has been designed to save energy, and deliver a perfectly smooth finish.

Maintenance and repair of salt bagging machines

Ensuring the longevity and efficiency of your salt bagging equipment is paramount to uninterrupted production. Concetti’s FFS-E salt bagging machine has been thoughtfully designed with ease of maintenance in mind. Its monobloc structure and accessible inspection doors make cleaning and upkeep straightforward, even in compact spaces. The bottom opening enables operators to access every corner of the machine, facilitating regular cleaning and minimizing the corrosive effects of salt.

For any mechanical adjustments or part replacements, our equipment includes detailed documentation and a user-friendly interface for quick troubleshooting. Additionally, our commitment to high-quality materials like stainless steel ensures reduced wear and tear, enhancing the machine’s lifespan and reliability. Partnering with Concetti means having robust salt bagging equipment that’s easy to maintain and repair, helping you focus on what matters most—your production goals.

Why choose Concetti North America

Concetti North America stands apart by combining world-class technology with localized support. We understand the importance of having dependable, real-time assistance close to your operations. Our North American team offers expert consultations, fast delivery of replacement parts, and on-site technical support to keep your salt bagging systems running smoothly.

From initial setup to ongoing service, our specialists work closely with your team to ensure that your equipment consistently meets your production demands. Choosing Concetti means not just investing in premium machinery, but also gaining a dedicated partner committed to your success. Whether you need training, spare parts, or immediate troubleshooting, our local presence ensures we’re always here when you need us most.

Do you want to find out more about our FFS-E salt bagging machine?