Production is becoming hectic these days. Therefore, companies need to boost their speed rate to be able to package more and faster. A bagging machine can be useful to achieve ambitious productive goals by streamlining the process and achieve a wide variety of products in different sectors.

You will delve into:

- What is a bagging machine?

- How does it work?

- Different types of bagging machine

- The several applications of a bagging machine

What Is A Bagging Machine?

A bagging machine is a semi-automated or fully automated piece of equipment that measures, fills and seals products into bags. It is a versatile technology that can be used in various industries for specific packaging purposes.

Through a weighing system, the device dispense just the right amount of product into the bags, ensuring precise portion control and consistent delivery based on the nature of the product. It can accommodate a wide range of materials - granular, powders and liquids.

How Does It Work?

Passing through several passages, these systems ensure that products are packaged accurately and swiftly.

Let’s discover how does a bagging machine work in this step-by-step overview.

- First, the product is benign fed into the machine thanks to gravity (free flowing products), belt (medium free flowing products) or screw (non-free flowing products) feedersthat guarantee that the material flows into the machine without congestions. Feeders may vary depending on the type of material.

- Bagging machines often incorporate a weighing system to measure the exact quantity of product that each bag should contain, improving consistency and minimizing waste.

- Once filled, the open end of the bag is closed by using heat or stitches, depending on the bag material and product requirements. Sealed bags are discharged from the machine onto conveyors for additional processing like boxing or palletizing.

Different Types of Bagging Machine

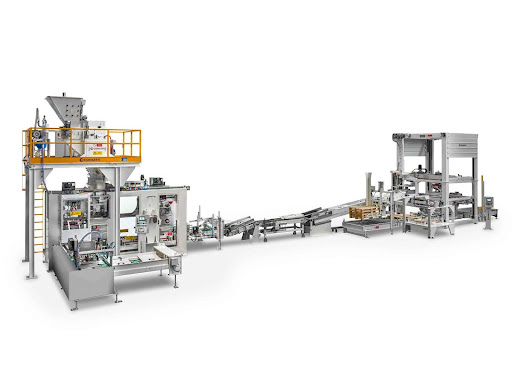

At Concetti, we have engineered different types of bagging machine to offer solutions that resonate with the target market. These models are suitable for different sectors and applications.

STARPACK®

The STARPACK® model has been developed for combining high-performance automation to technology. Concetti has designed this system to deal with high throughput demands. It is the perfect bagging machine for packing granular and semi-granular products, such as seeds, cereals and fertilizers. This model is capable of reaching a productive capability of 1,600 bags/hour, handling bags from 22 to 100 lbs.

IGF

Flexible and highly customizable, the IGF bagging machine can handle products from granular to powdery substances, including pet food, animal feed, seeds, food products and salt. It is capable of handling bags from 4 to 44 lbs, achieving a productivity rate up to 1,200 bags/hour.

The IGF machine is available in two special configurations: IGF Pura, specifically designed for food powders and IGF Gemini, engineered to prevent cross-contamination between batches.

IMF

The IMF bagging machineis particularly suitable to handle bulk products, from granular to powdery. It can deal with different bag sizes and weighs, offering a high capacity output of up to 1,800 bags/hour. The effectiveness of this bagging machine is enhanced by its dual filling stations, to maintain high performance at all times, reducing downtime.

Recently, Concetti has taken the IMF equipment to the next level, enhancing all the distinctive features of this model. In the end, Concetti has launched IMF ālĕs, a brand new linear bagging machine, specifically designed for the pet food industry. It promptly manages a bag range from 6 to 44 lbs with a production capacity up to 2,000 bags per hour.

IPF

The IPF bagging machine has been specifically engineered to work with small-format bags, with a weight range from 2 to 11 lbs. IPF stands out for its extreme versatility, allowing the management of all types of materials and the most innovative sealing techniques. Every stage of the packaging process is PLC-controlled from an HMI panel.

Are you interested in one of our bagging machine models for your business

The Several Applications of a Bagging Machine

One of the main advantages of Concetti’s bagging machines is that they can easily adapt to the most diverse sectors. In this way, they become a landmark of versatility, as they can cater to the requirements of various industries while delivering excellent results.

As for food packaging, these systems reveal to be extremely flexible as they can bag a variety of products, from cereals to spices. At the core of this type of operation, there is the need for bags that are suitable for food contact. Another aspect that needs to be underlined is the perfect sealing of the package that preserve the freshness and integrity of the product, ensuring its conservation in optimal conditions.

The agricultural sector can benefit from the action of bagging machines as they allow the quality of seeds and feed during the packaging process and transportation. Being equipped with a weigh system, it is also possible to count the seeds fed to a single bag for a more precise operation.

The Concetti bagging machines are the right choice for the chemical industry, as well. In fact, our PLC-controlled devices can handle safely even the most corrosive and hazardous substances, without manual operations needed. This will enhance productivity and welfare of operators.

Another core sector is that of building materials, such as dry mortar, Premix, concrete and cement. To handle these products, Concetti provides different types of packaging lines, based on the weight range. In fact, our FFS systems can seamlessly deal with building materials up to 88 lbs while for heavy and dusty products, we need bulk bags (1,102 - 4,409 lbs) that contribute to the correct sealing by deaerating the material, first.

If you are interested in discovering our bagging machine solutions for your business